Full availability is one of the goals in sawn timber and pulp production. The criteria for safety at work and product quality are already stringent, but there is always room for improvement, even if you are a leader in the field, says Tuomas Arminen, Metsä Fibre’s Development Director. These, he explains, were the drivers of the adoption of 5S.

“5S is an internationally recognised, tried and tested method. We wanted to improve efficiency and safety at work at our production units across Metsä Group by setting up a common standard, based on 5S, for tidiness and order.”

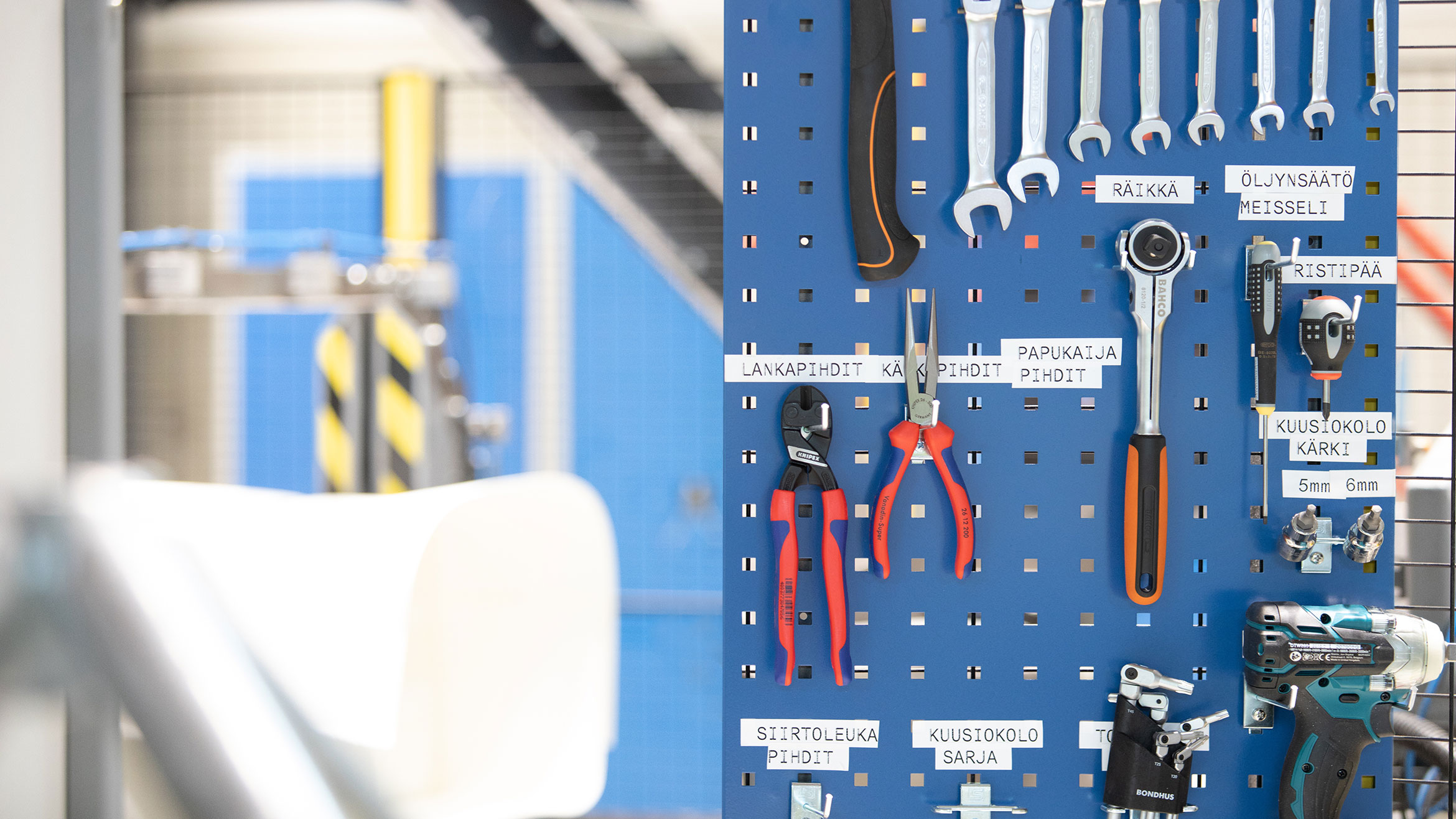

The method builds on visual observation, the organisation of workstations and standardisation of work methods. Time is wasted and it is difficult to concentrate if workstations are untidy, tools are lying around, objects are misplaced and you constantly have to look for things or need to move unnecessarily between different departments. Disorder also creates the risk of tripping or having an accident.

The goal of the 5S method is to reduce disorder and wasted time by fixing defects and gradually adopting a work culture in which tidiness and ease of work are as self-evident as keeping order at home.

A comfortable workplace is a productive workplace

The deployment of 5S has been supported with training and follow-up audits and inspections carried out by personnel. The method concerns all employees, from directors to operators, providing good support to production efficiency.

Anssi Meuronen, manager of the Lappeenranta sawmill, is satisfied with the results to date.

“In 2021, we focused on deployment, and this year, we will obtain reliable group-wide information about the improvements achieved through 5S. It is crucial to understand that this is not about a single project but rather about a process of continuous improvement, which is a part of our operating culture. The 5S method has met with an enthusiastic response because its benefits become quickly visible in daily life.”

Well-organised production is obviously clear to others, as well.

“Our production units receive a continuous flow of customers and other stakeholder representatives, so a tidy and comfortable environment is a sign of safe, well-planned and efficient operations. We do not waste time looking for tools, but can instead monitor production and anticipate future maintenance and repair needs,” says Janne Rantanen, manager of the Rauma pulp mill.

Human hands always needed

Although modern sawmills and pulp mills feature a high level of automation, manual work is not yet about to disappear.

“However advanced the automation, we also need human hands. Loose screws need to be tightened, engines at the end of their life-cycle must be replaced and the premises must be kept tidy. As long as the process is monitored and controlled systematically, we will not face unpleasant surprises, such as an unscheduled shutdown caused by a broken engine,” says Arminen.

In the long run, the 5S method will also lead to fewer close call situations, a decrease in sickness absences, improved workplace wellbeing and fewer production disturbances.