The entire tree is utilised

We use every part of the tree for the purpose it is best suited for: logs are delivered to our sawmills, while pulpwood is used for pulp, biochemicals and further processing into other bioproducts. Branches, treetops and bark are used for bioenergy production. And the wood chips our sawmills produce as a side stream are used in our pulp production.

In addition, we make the most of the natural qualities of wood from the moment it is harvested in the forest. For instance, we cut each log with our customers’ needs and end products in mind in the forest. This allows us to ensure that the end products are of high quality and that not even a splinter of valuable raw material is wasted.

Our unique bioproduct mill concept

The unique bioproduct mill concept developed by Metsä Fibre enables the future expansion of our product range with new bioproducts that possess an increasingly high added value. The bioproduct mill concept is based on the idea that raw material and production side streams are used to produce various bioproducts, which can replace fossil-based materials and fossil fuels.

We constantly develop our resource efficiency. For example, at the Äänekoski bioproduct mill, we have expanded the mill’s closed chemicals cycle by using the mill’s odorous gasses to produce sulphuric acid. This also minimises any sulphate discharges into the waterways. In addition, Metsä Fibre’s Joutseno, Äänekoski and Kemi mills produce product gas from bark. This product gas is used as a fossil-free fuel in the mills’ own processes.

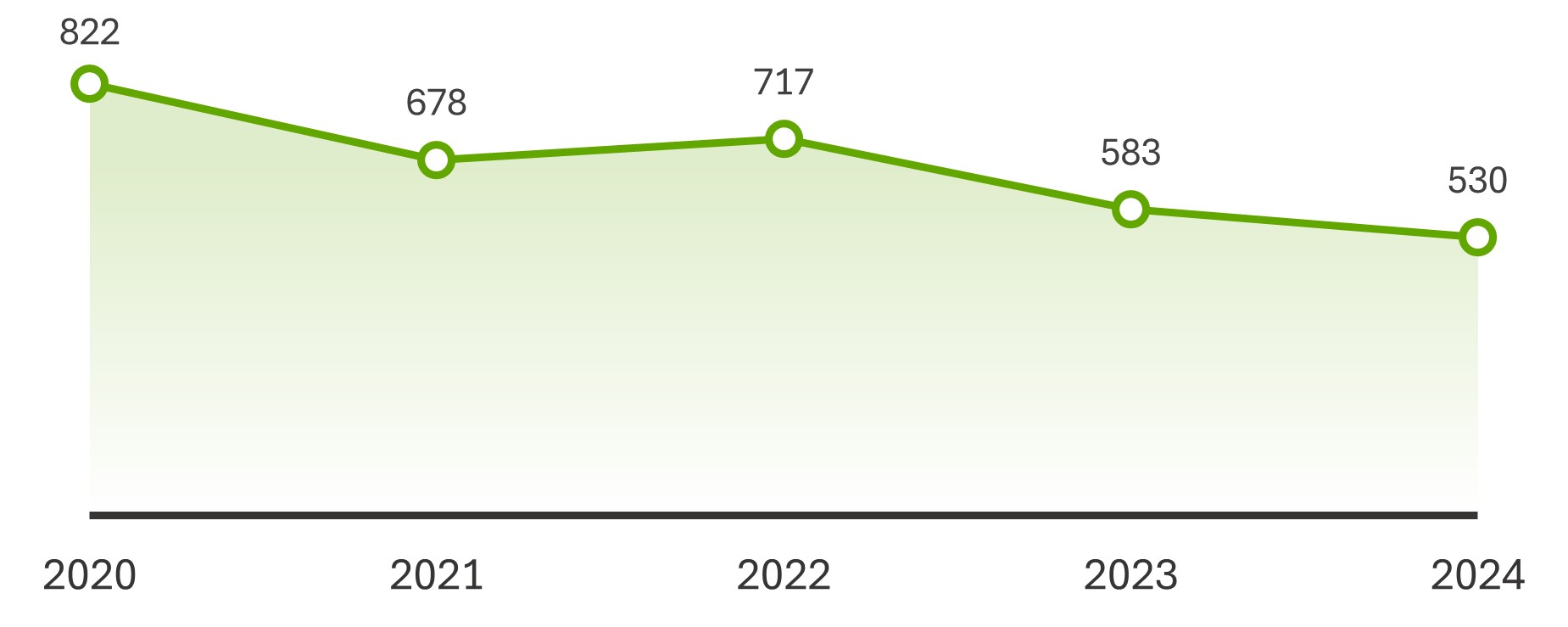

Fossil fuel use, GWh

| Five year trend 2020–2024, Metsä Fibre total |

|

Fossil-free future

Our 2030 target is that all our mills to operate without fossil fuels. Main part of fuels used in our production are already biofuels.

We are also a significant producer of bioelectricity, generated during pulp production when black liquor, which consists of wood and cooking chemicals, is combusted in the recovery boiler. At the same time, the cooking chemicals used in the pulp process are converted into a reusable form.

We generate much more electrical energy than we consume. In addition to our own production, we supply bioenergy in the form of district heat to local communities and electricity to the national grid. Improving the energy efficiency of our production units is a key element of our investment targets.