Packages of sawn timber shipped out from Metsä Fibre’s sawmills are usually wrapped in a plastic hood or wrap. This protects the sawn timber from dust, dirt and water during transport and intermediate storage.

“The fitted hood is placed over the sawn timber package once it has been banded and stamped with the shipping marks. The hood covers the entire package and is held in place with staples and plastic bands. The hood sizes are designed according to the height, width and lengths of the packages, so that the sawn timber is entirely covered by the hood,” says Jani Riissanen, SVP, Sawn timber production and wood supply steering at Metsä Fibre.

Sawn timber is also occasionally protected by plastic wraps resembling a hood. These are not, however, fitted to the shape of the packages beforehand. The wraps are delivered to sawmills in the form of rolls, and then cut to suitable dimensions in the sawmill’s packing centre and placed over a bundle of sawn timber in a hood-like fashion.

Both hoods and wraps have their advantages.

“Protecting the timber with a hood is easier, but the hood size rarely precisely matches the size of the package that needs covering. A wrap can be cut to fit the dimensions of each individual package of sawn timber and is therefore primarily used when the bundle isn’t of a standard size,” says Riissanen.

Sawn timber must be packaged to withstand tough conditions

According to Riissanen, the properties of the hoods and wraps, and the material used in their production, are the result of careful consideration. Woven recyclable polypropylene has proven to be a practical and functional choice. It’s durable and strong, and protects the timber without tearing, even in the most demanding conditions. The surface of polypropylene also allows for the easy addition of the desired print and provides a non-skid layer.

“Our choice of material is focused on quality rather than the cheapest price. The properties of the hoods and wraps have also been extensively developed. Their surfaces contain a transparent non-skid layer that increases friction and prevents packages stacked on top of one another from toppling down. It also reduces their slipperiness when they’re lifted, and during other port and storage handling. The black colour in the plastic’s bottom layer further protects the timber from the sun’s UV rays,” says Riissanen.

Recyclability of sawn timber hoods is important

“We’re in the process of developing a recycling service with the producers of protective plastics, which will include the collection of hoods and wraps from customers. Any hoods damaged at our own mills are already returned to the manufacturers or other partners for recycling,” says Riissanen.

Riissanen estimates that at least 70 per cent of the timber loads shipped from Metsä Fibre’s sawmills are protected with plastic. In some countries, such as Germany, people have more reservations about plastic. Timber batches transported within the borders of Finland are also not always protected with plastic.

“Often the products that are not protected are transported directly to a customer’s production storage on trailers. The transport distance is short and the products are not held in intermediate storage, so the need to protect them isn’t as great,” says Riissanen.

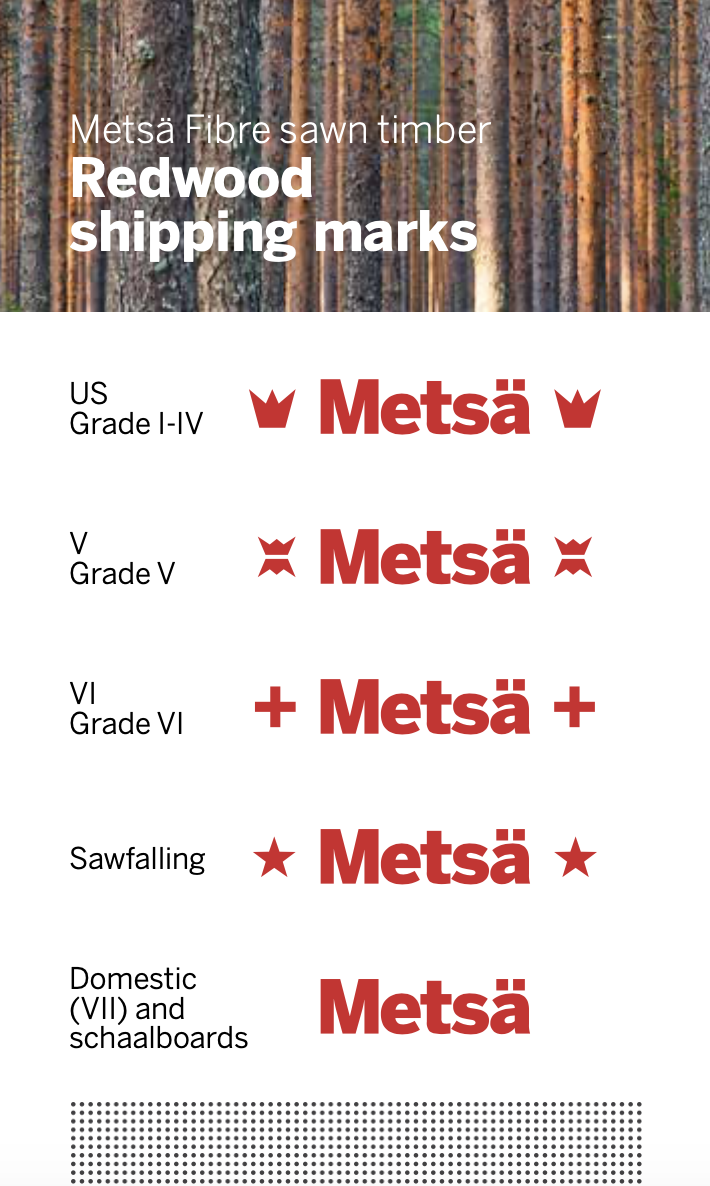

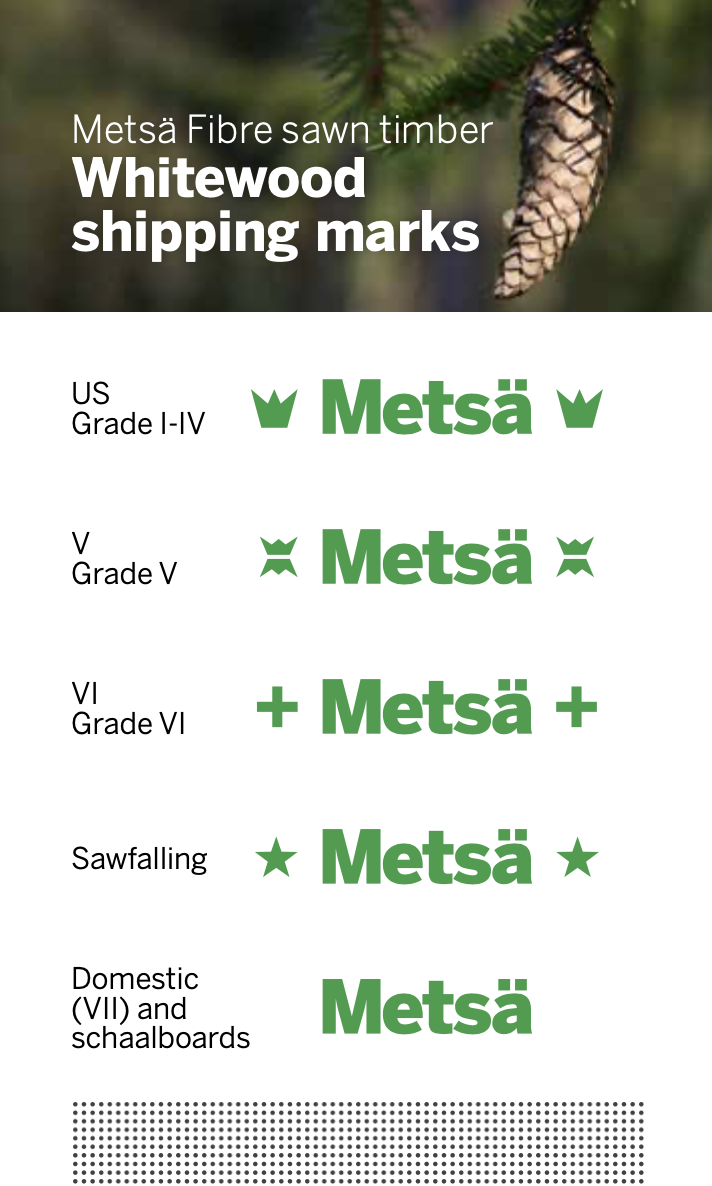

Shipping marks indicate the origin and properties of the sawn timber

The shipping marks stamped on the ends of sawn timber inform the recipient who the timber producer is as well as the type and grade of the sawn timber.

Sawn timber is classified into various grades based on its technical and visual properties. The technical properties include the dimensions, moisture content and warping of the sawn timber. The visual properties include the location, size, number, quality and composition of knots and warps.

The grading of northern sawn softwood employs a seven-step scale, which includes the main grades US I – IV as well as V, VI and VII. The US grades (US standing for unsorted) that are the highest contain the grades US I – IV. The majority of Metsä Fibre’s spruce sawn timber, which is of a consistent quality, falls under the US I – IV grades.

The shipping marks which were all sawmill-specific have been replaced by the new brand image. This has led to a new design based upon the Metsä logo and a mark indicating the timber’s grade. For spruce sawn timber, the logo’s base colour is green, and for pine sawn timber, it is red.

“Before, there could be sawmill-specific differences in the finishing of sawn timber, which justified the use of sawmill-specific shipping marks. Now the quality of the sawn timber is identical, regardless of its production location, so we are able to harmonise the shipping marks.”

“This supports the building of our brand and improves customer service. Our customers can contact our centralised sales service for any questions related to our sawmill products,” adds Riissanen.