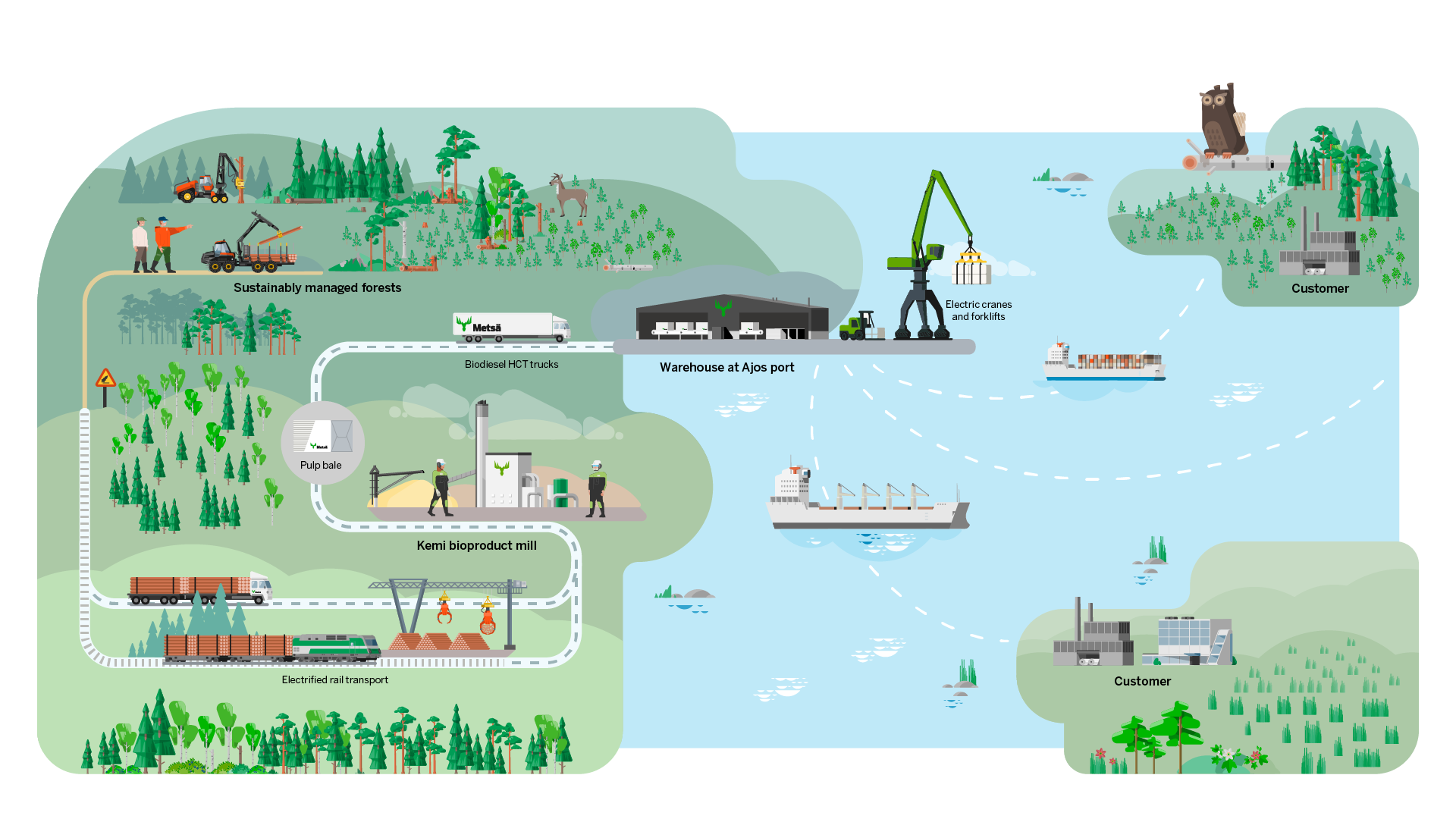

Metsä pulp travels from Kemi to international markets as part of a carefully planned and responsibly executed logistics chain. Every shipment shares the same goal: to ensure the pulp arrives on time under all conditions, allowing customers’ production to continue without interruption.

Meticulous planning and close cooperation with ports, transport companies and customers enable smooth deliveries to Europe and more distant markets alike. The supply chain is designed to withstand long distances and varying conditions, ensuring schedules are maintained even in exceptional circumstances. The same long-term approach applies to environmental responsibility: logistics solutions are continuously developed to be more energy-efficient and lower in emissions.

Metsä Group is committed to reducing transport-related greenhouse gas emissions by 30% by 2030 compared to 2022 levels. Responsibility is an integral part of the Kemi bioproduct mill’s logistics – solutions that reduce Metsä Fibre’s own carbon footprint also help customers achieve their climate targets.

Responsible logistics begins in the forest

Most of the pulpwood used at the Kemi bioproduct mill is transported via an electrified rail line. Modern electric locomotives haul loads of up to 2,500 tonnes – around 20 % more than previously used locomotives – reducing traffic volumes and emissions.

New logistics routes were designed and built for both truck and rail traffic in the vicinity of the factory, avoiding intersections with other traffic and improving safety in the area.

Automation and biodiesel enable fossil-free transport from mill to port

Pulp sheets produced at the mill are bundled into bales and grouped into 2,000 kg export units. These units are automatically loaded from production onto specially designed trucks without manual forklift work, supporting the mill’s fossil-free operating model.

Transport to the Port of Ajos is handled by specially constructed HCT trucks (High Capacity Transport).

“HCT trucks can carry 72 tonnes of pulp at a time – about 1.5 times the capacity of a standard truck. This reduces the carbon footprint of transport by 30%”, explains Mikko Hirsimäki, Regional Logistics Director at Metsä Group.

The biodiesel-powered trucks deliver the pulp units to the port, 15 kilometres away, where they are automatically unloaded into Metsä Fibre’s 37,000 m² product warehouse. The warehouse operates fossil-free: electric forklifts move the bales into storage and feed them to an electric crane for vessel loading. This reduces carbon emissions and noise levels while improving safety.

“The design of the Kemi bioproduct mill focused on a safe, efficient and low-emission logistics chain from the mill to vessel loading. This was considered in the choice of pulp handling and loading equipment as well as the layout of the storage area at the quay”, Hirsimäki adds.

Global exports rely on resilient logistics

Global exports rely on resilient logistics

From the Port of Ajos, pulp units are shipped worldwide – to Europe, the Americas, Asia and Africa. For example, pulp reaches Vlissingen in the Netherlands in 5–6 days, while the sea voyage to China takes 8–9 weeks.

For pulp deliveries to Asian markets, Metsä Fibre uses the latest vessels designed for Kemi traffic, whose modern technology enhances environmental efficiency.

To ensure reliability over long distances, Metsä Fibre maintains an extensive network of port warehouses, enabling rapid deliveries across the globe. This network and diverse routing options provide flexibility and security even in exceptional situations – for instance, customer deliveries continued without disruption during the Baltimore bridge collapse in the USA.

Ready for export in all conditions

Kemi’s location at the northernmost end of the Gulf of Bothnia brings unique challenges to logistics, especially in winter. Despite temperatures dropping below –30°C and thick ice cover, the Port of Ajos operates at full capacity year-round.

Finland’s world-class icebreakers keep sea routes open even in Arctic conditions, ensuring reliable deliveries in the depths of winter.

“Delivery reliability is secured through close cooperation with Finnish icebreaking authorities and by preparing alternative shipping plans with shipping companies. In a typical winter, icebreaking is required in the Gulf of Bothnia from late November until the end of April”, says Marko Korhonen, Vice President of Maritime Logistics at Metsä Group.

Responsible marine logistics supports customers’ climate goals

Marine transport and its sustainability are developed in collaboration with logistics partners.

“Shipping accounts for around three per cent of global greenhouse gas emissions, so achieving reductions is crucial, as most of our products are delivered by sea”, Korhonen explains.

Significant progress has already been made. The fleet has been upgraded with electric hybrid vessels, and partial transition to renewable fuels has reduced fossil fuel use. At the same time, improving energy efficiency through route optimisation and port solutions has cut emissions. However, there is still work to do:

“Port electrification is a key part of the solution. When vessels can use shore power in port, fuel consumption and local emissions are significantly reduced. Digitalisation also opens new opportunities for real-time monitoring and operational optimisation, improving transport energy efficiency. Developing and implementing these solutions requires close cooperation between shipping companies, ports and authorities”, Korhonen summarises.

At the same time, transport solutions aim to reduce Metsä Fibre’s own emissions and pave the way towards Metsä Group’s 2030 sustainability targets. A finely tuned logistics chain also supports customers in achieving their climate goals:

“Our fossil-free Kemi Bioproduct mill and low-emission logistics solutions across the supply chain enable a low carbon footprint for our customers’ products. Our collaborative approach ensures that Metsä Fibre’s responsible choices deliver real climate benefits for our customers and strengthen their position in their own markets”, concludes Metsä Fibre’s Sustainability Manager Marko Ruottinen.