“Our primary goals in marine logistics include making use of natural transport flows and transport hubs. This principle works extremely well,” says Jyrki Ranki, VP, Marine Logistics at Metsä Group.

Helsinki and Kotka are Metsä Fibre’s most important ports of export for the transportation of both pulp and sawn timber.

“Rauma’s importance as the port of departure is also about to increase, thanks to the new Rauma sawmill investment.”

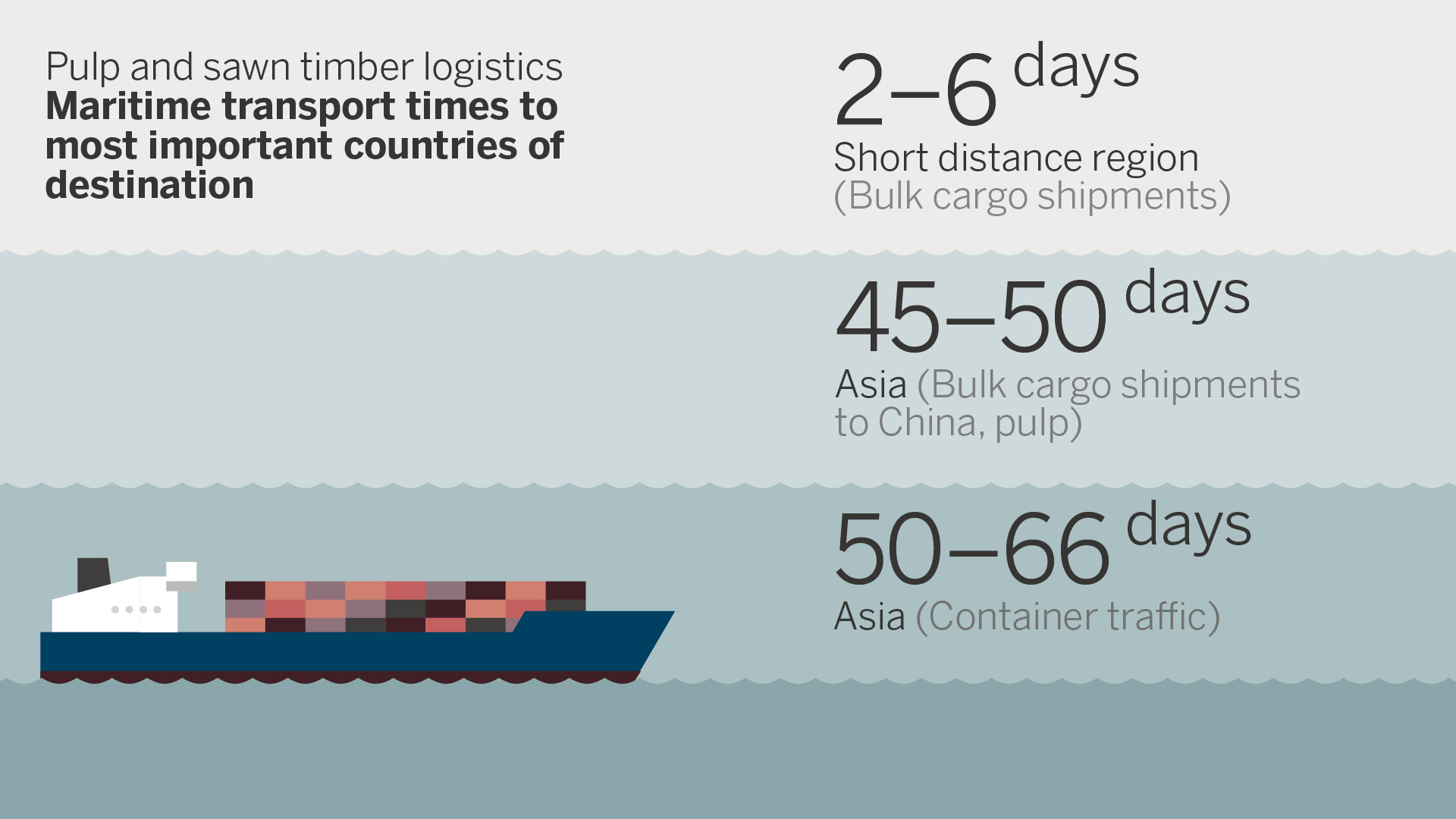

Container traffic is one of the most important operating methods in the marine logistics of pulp and sawn timber. The balance between exports and imports plays an essential role in it.

“This balance in the traffic has an impact on both the availability of capacity and the cost level of deliveries,” says Ranki.

At the moment, Finland’s biggest container port is Kotka, followed by Helsinki. The balance between import and export traffic in Helsinki is the best in Finland. The volume in Rauma is smaller than in Helsinki or Kotka.

Metsä Fibre can use the containers arriving to Finland in its own exporting.

“We use the containers that have arrived in Finland in the returning traffic to Asia. For the time being, these three ports are the only ones where this is possible.”

The containers depart Finland as feeder traffic to the ports and harbours of the Atlantic Ocean, such as Hamburg, Rotterdam and Antwerp. There the containers are loaded onto big container ships that transport them to Asia, the Middle East or the Mediterranean.

Committed and motivated partnerships

Ports that handle plenty of inbound and outbound traffic generally tend to have a good level of services and a number of port operators.

“We appreciate commercial competition in the port. The competitive situation is apt to develop operations and improve the level of services,” says Ranki.

“The key thing is to find partners with a good reason for developing their operations and growing with us. Committed and motivated partners are an essential factor in developing cost-effectiveness and delivery reliability.”

Bulk cargo transport relies heavily on shipping companies, which carry raw materials needed by Finland’s industrial sector. This generates two-way transport flows.

Short-distance cargo flows run on a partly triangular route from Scandinavia to the North Sea, and from there through the Baltic countries back north.

“We ship a little pulpwood from the Baltics to Finland. The same ships carry pulp and sawn timber to the North Sea ports. When the ships return to the Baltic Sea, our shipping partners sell cargo for transports suitable for this traffic.”

In both container and bulk cargo traffic, the selection of the shipping company is dictated by the company’s ability to carry out the transports according to Metsä Fibre’s needs.

“The partners we are looking for are shipping companies that can provide us with a sufficient fleet suitable for our needs, in a flexible manner.”

Logistics managed centrally

Metsä Fibre’s operational logistics, purchasing and partnerships are operated and managed centrally at Metsä Group level.

“Our purchasing power grows significantly when our procurements are made by Metsä Group. We are more interesting to shipping companies as a group. That allows us to provide them with more business opportunities.”

Product deliveries are managed by Metsä Group’s maritime logistics service centre, which works very closely with business divisions, shipping companies and ports. It tries to anticipate as accurately as possible upcoming changes in demand for pulp and sawn timber, as well as long-term transport needs. It optimises transport for all customer deliveries. Logistics coordinators at the service centre reserve the shipping capacity required, monitor the progress of deliveries and keep the port of entry and the recipient up to date.

Metsä Fibre’s sawn timber and pulp have partly converging target markets. In these cases, the transport of the products can be combined for the achievement of better operational and cost-efficiency.

“We look at potential combined transports from the perspective of both cost and customer service benefits. For example, the capacity of the bulk cargo ship that transports pulp products to China once a month also enables the transport of sawn timber according to the part shipment principle.”

Extensive tracking both for pulp and sawn timber

The product tracking of pulp is based on Metsä Fibre’s own RFID system. Every bale of pulp leaving the mill is furnished with an RFID tag, based on which the bale can be identified.

Readers at the mill as well as the ports of departure and destination register the new location of each pulp bale automatically and transmit the information to Metsä Fibre’s tracking system.

Sawn timber customers can track the status and location of their deliveries in real-time through the online Track & Trace service. The service also provides an estimated time of delivery for the order.

The tracking during the maritime transport is based on updates received from the shipping companies. The ships’ location data is entered on the servers of external service providers, from where Metsä Fibre can transfer the data to its own system.

In bulk cargo shipments, the shipping companies enter their schedule updates directly in Metsä Fibre’s system or send the data to the staff of the operational logistics who enter the data in the system.

Digitalisation reduces the emissions

Shipping companies take advantage of digitalisation in route planning, among other things.

“Route calculations optimise both fuel consumption and the safety of the transport. The aim is to avoid bad weather fronts, for example, to improve both cost-effectiveness and customer service. Safety at work improves and the products being shipped remain intact.”

The planning also accounts for the situation at the destination ports.

“A single container ship unloads cargo at several ports of destination along its route. Route optimisation aims to avoid the rush hours of ports by directing ships to run slower when necessary, saving on fuel consumption by doing so,” says Ranki.

Successful optimisation makes a big difference to customers, given that fuel consumption is one of the most important individual factors in the costs of marine logistics.

It is the whole that counts in managing the transport chain

While every detail is significant in managing the transport chain, in the end it is the whole that counts. This means achieving a good level of delivery reliability and turnaround times as short as possible. At the same time, carbon dioxide emissions can be reduced and the transport costs can be slashed.

“The markets for our products have expanded in step with our increased production efficiency and volumes. The distances have increased, and the level of customers’ demands in terms of our delivery chain have risen. The capacity of both our delivery chain and the related network of partnerships is a key success factor for us,” says Jyrki Ranki.

This article was originally published in issue 2020–2021 of both Fibre Magazine and Timber Magazine. Take a look at the magazines.