Wood is a strong, lightweight construction material. These natural qualities bring multiple positive consequences for both individual constructors and societies undergoing heavy urbanization. Wood is also the best option when building an extension on top of existing buildings. Engineered wood materials like Metsä Wood’s Kerto® LVL (laminated veneer lumber) make construction fast, light and green.

Lightweight material

The lightness and strength properties of engineered wood products, such as Metsä Wood’s Kerto LVL, provide a very attractive and resource-efficient option for construction in urban areas. Using prefabricated Kerto LVL elements and modules has multiple benefits. Furthermore, the lighter the building parts are, the less energy is needed for transportation and erection, saving time and money during the construction project.

Lighter structures made of wood also require lighter foundations for the building.

“This, in turn, leads to cost savings as less piling, fewer construction materials and less time are needed,” points out Matti Kuittinen, an architect and researcher from Aalto University.

LVL for structures

The wood used in structural members compares well in strength to concrete and steel alternatives. The wood’s excellent strength-to-weight ratio ensures that less wood is needed to achieve the same strength as with steel and concrete beams.

The “specific strength” of construction materials is the ratio of their strength to their density. This figure is 5.22 kNm/kg for typical concrete, 63.1 kNm/kg for average stainless steel and in the range of 115 to 521 kNm/kg for different species of wood.

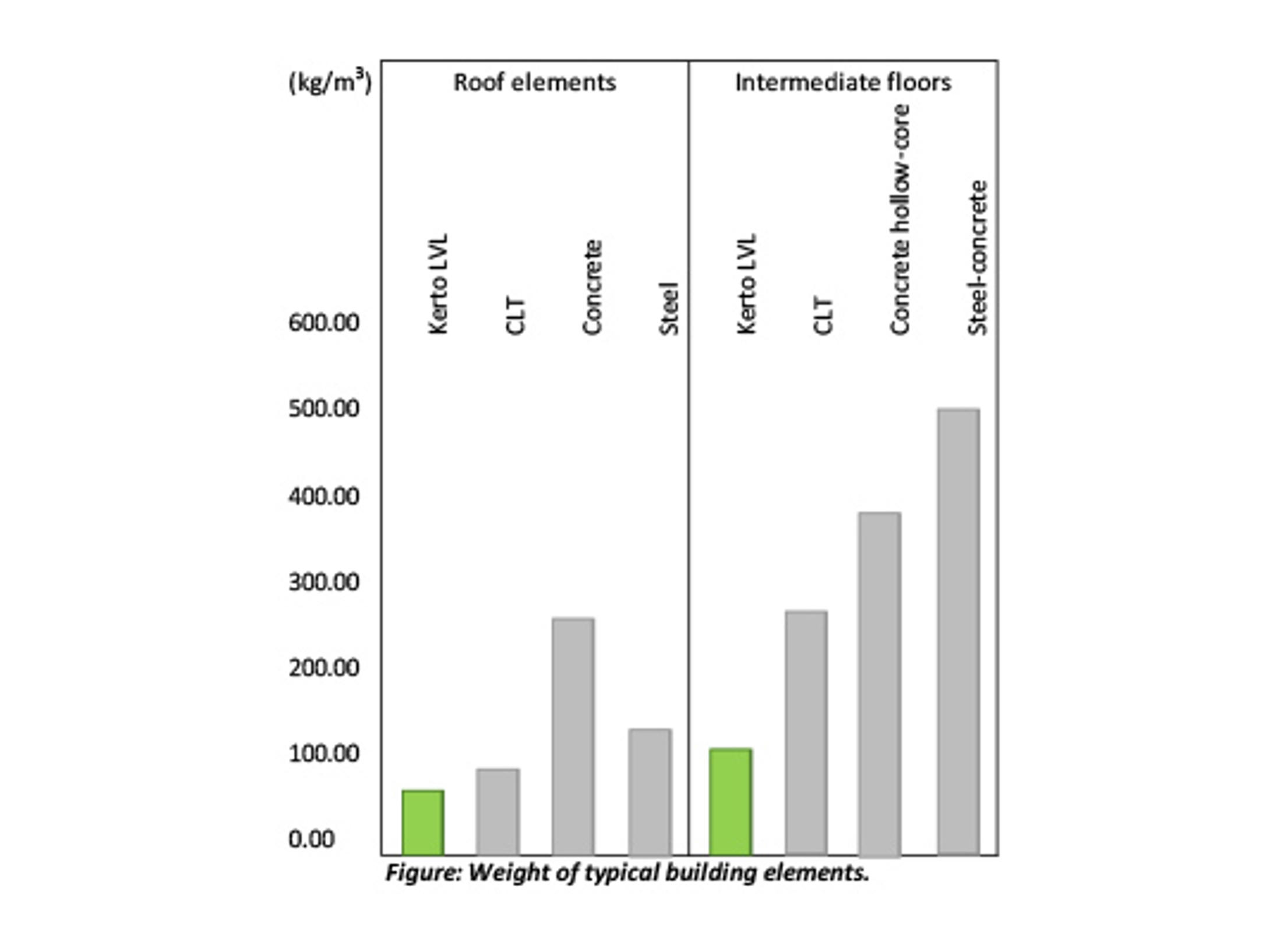

When comparing typical1 alternative structure types (LVL, CLT, concrete and steel) for roofs, and intermediate floors, the calculations show that typical structures made of Kerto LVL are the lightest options.2 This is due to the strength and lightness as well as the optimised amount of LVL in the elements.

Strong extension with light wood

The built environment is going through an era of refurbishment. The need to renovate building service systems, such as sewage and ventilation, is a remarkable driver of residential refurbishments. To finance these operations, new storeys are, in some cases, being added on top of existing buildings.

“Adding new layers on the roofs of old buildings requires careful planning. The structures may have been calculated according to different standards than are applied today, or the materials may have been damaged during their service life,” Kuittinen says.

Using lightweight building materials, such as wood, is one valid option to bypass this problem.

The era of extensions

Wooden elements are a top option when adding new storeys on top of an existing building. One of the most essential advantages is the smaller weight of the roof structure, which enables building to a lighter foundation.

In Poissy, near Paris, 33 new apartments were constructed on top of a group of existing residential buildings. Construction began in September 2016, and due to prefabrication and the light wooden structures, it took only six months to complete.

"What's interesting about this solution for vertical urban development is the prefabrication," says Laurent Pillaud, architect at Virtuel Architecture. "Each apartment is made up of three or four modules and one roof; the production of the modules took one month. The modules were installed directly on the rooftop, each in one day."

Most construction companies have experience in building extensions for single-family homes and are now turning their focus to large-scale extensions to office buildings, hotels and large residential buildings. This, combined with the increasing acceptance of timber frame construction, means that the potential for light wood extension is becoming considerably higher.

Sources

- Rakennustieto, “Rakennusosien kustannuksia [Costs of building component],” Rakennustieto, Helsinki, 2016.

- P. Silver, W. McLean and P. Evans, Structural Engineering for Architects, London: Laurence King Publishing Ltd, 2013.

- R. Konstantinou, Facade Refurbishment toolbox: Supporting the Design of Residential Energy Upgrades, TU Delft, Delft, 2014.

- M. Langen, “Building additional floors with wood”, Metsä Wood articles, 2016.

- H. Berger, Light Structures, Structures of light: The Art and Engineering of Tensile Architecture, Basel - Boston - Berlin: Birkhäuser Verlag, 1996.