To achieve a top-quality sophisticated results in concrete construction, the planning and quality of formwork systems play a decisive role. The new Metsä Wood DURAForm formwork panel line from Metsä Wood features high stability and reduced deformation, despite its low weight. The birch plywood panels made of sustainably produced raw materials are maintenance-free and can be used up to 200 times. They yield particularly smooth surfaces while complying with the principles of circular economy circularity.

Smooth finish

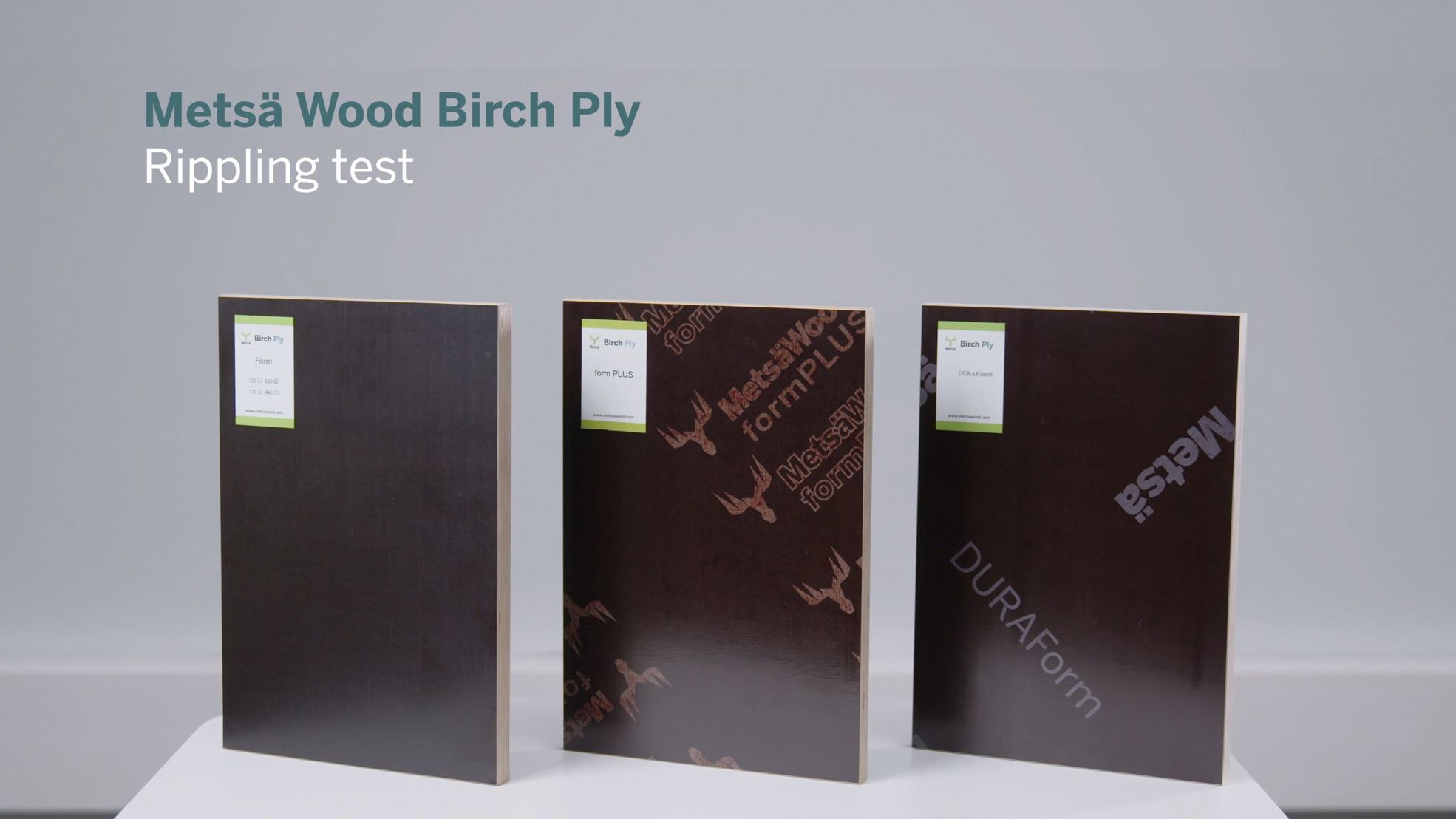

The Metsä Wood DURAForm panels are available in a variety of standard sizes and thicknesses for a multitude of applications, featuring a width of up to 1.5 metres and a length of 3.66 metres. The product is based on resource-friendly sustainably produced Finnish birch plywood. The plywood in turn is produced using 1.4 millimetre thick crosswise glued veneers. To achieve higher bending resistance and durability, the panels can be ordered for use in especially demanding formwork applications with specially aligned veneer structures. The dimensional tolerance of the elements complies with standards at ±0.1 percent for length, perpendicularity and edge straightness. The composite coating applied single-sided on the concreting side is moisture-proof, reducing rippling as a result, allowing for a smooth concrete surface from the first use. The panel edges are additionally sealed with acrylic paint against the penetration of humidity.